We are capable of recreating any timber profile/moulding up to a size of 300mm x 150mm. This includes anything from a simple dressed board up to a complicated moulding.

Our staff are well trained and very knowledgeable, collectively possessing over 50 years of experience in processing timber.

Please contact us for a quote on all your timber-processing needs.

Flooring Profiles

Weatherboard Profiles

Architraves & Skirting Profiles

Any Timber Moulding Profiles

Standard & Castellated Battens

- Door Jambs - Reveals - Sills - Decking - Sarking - Panelling - Fascia -

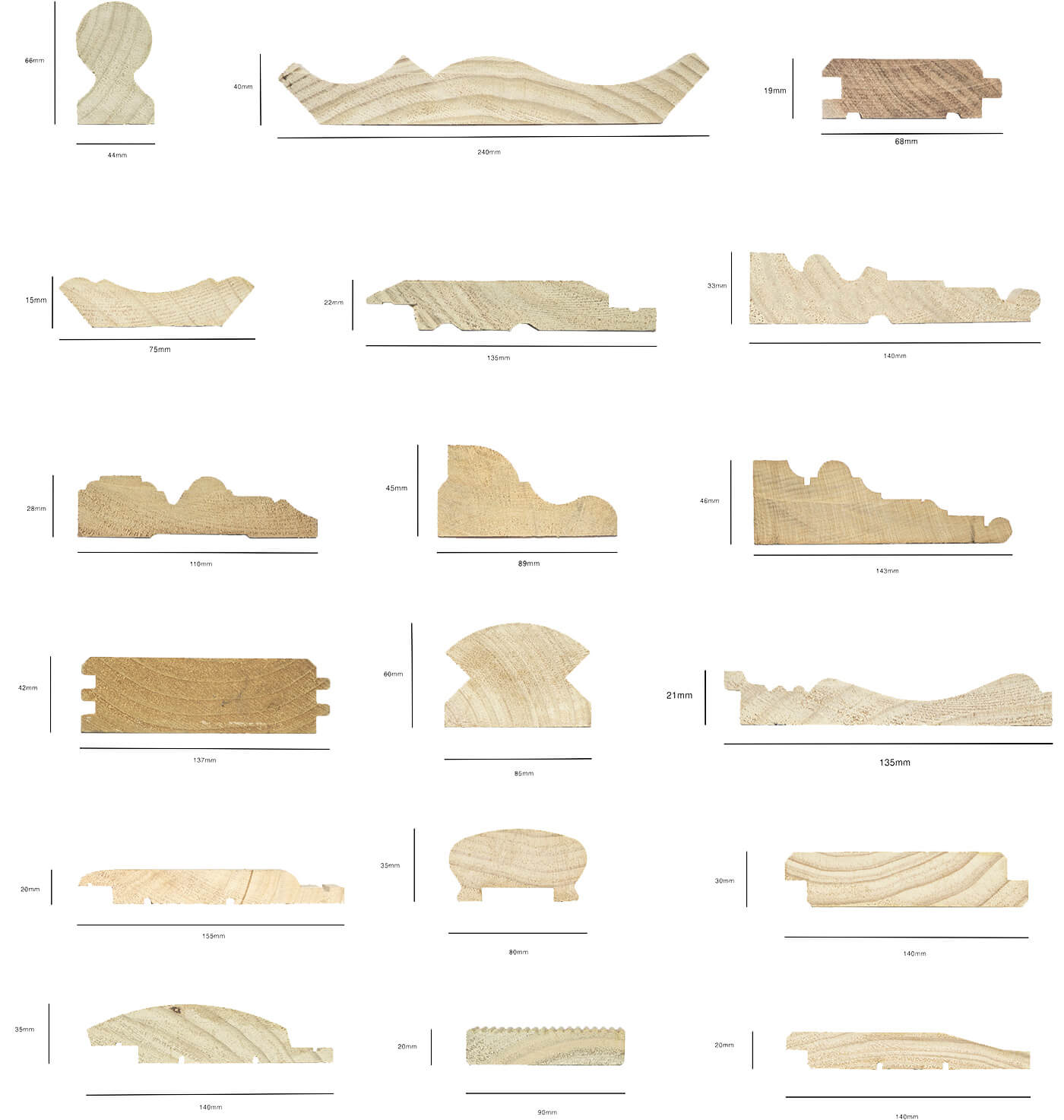

Below are some examples of what we are capable of but are not limited to

Our Machinery

Two Leadermacs & 1 SCM

- Our primary timber-moulding machines.

- Maximum machining size 300mm x 150mm in-feed.

- One machine purchased in 1995 and still produces a perfect finish.

- Two machines purchased within the last 3 years and are of the most up-to-date technology available for creating timber mouldings.

- All 3 machines are capable of processing thousands of lineal metres of timber per day.

Paul Optimizing Docking Saw

- Computerised machine best suited for large runs that require the timber to be cut to a certain length.

- Eliminates timber defects with a laser eye.

- Can program multiple different lengths as required.

- Capable of high-volume production

Stenner Saw Band

- Cuts timber to size with minimum kerf, making it suitable for further machining or kiln-drying.

- Can change the thickness and/or width of timber.

- Used to create bandsawn face on weatherboards / T&G Panelling

- Maximum size 250mm x 100mm.

End matcher

- Produces a factory finish tongue-and-groove on the ends of flooring pieces to lock timber flooring on all 4 sides.

- Ideal for high-priced flooring, reducing unnecessary wastage

Template Maker & Knife Grinder

- A computer-controlled machine that carves out plastic templates to the required timber profile.

- This template is then placed into the knife grinder, which follows the template (similar to how a key is cut) and grinds the steel knife to the timber profile.

- The steel knives are then set into timber-moulding machines (SCM1 & Leadermacs) which in turn create the timber moulding.